Journal of Novel Physiotherapy and Physical Rehabilitation

Padded geriatric headbands to mitigate fall injuries

Yong K Kim* and Armand F Lewis

Cite this as

Kim YK, Lewis AF (2024) Padded geriatric headbands to mitigate fall injuries. J Nov Physiother Phys Rehabil 11(1): 011-015. DOI: 10.17352/2455-5487.000104Copyright

© 2024 Kim YK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.In response to information that more older Americans are dying from accidental falls, UMass Dartmouth researchers have addressed the problem by employing Flocked Impact Energy Absorbing (FEAM) materials to design special Wrap-Around Padded Headband (WAPH) garment structures. Such headband structures are intended for use by geriatric patients who might be vulnerable to falling. Overall, head-worn WAPHs should serve as head protection therefore mitigating any serious head injury that may occur during any such falling mishaps. The designed geriatric headbands feature a customizable, one-size-fits-all, linearly stretchable, wearer-comfortable design. Additionally, the particular wrap-around feature provides an overlap in headband over-wrap length such that some parts of the head perimeter (forehead or back-head) zone have a double thickness of the FEAM impact force material protection. Impact Force Absorbing (IFA) measurements carried out on FEAM employing headband material show that the IFA properties of the designed headband are superior in impact absorbing properties compared to non-IFA material containing stretchable fabric. As a means of determining how the designed WAPHs will absorb sweat, water immersion studies were carried out on some representative headband materials. The designed headbands should also be able to manage body heat. Self-wearing-trials of some WAPH prototypes demonstrated that they are very wearer comfortable. However, more experimental studies must be carried out to optimize the IFA properties of the FEAM element used in fabricating these WAPH garments.

Introduction

It has come to our attention that more older Americans are dying from accidental falls, especially falls that cause head injury [1]. Following, our research on sport and military headbands and sweatbands has led us to the notion that such technology could be adapted to the creation of impact force-absorbing headbands for geriatric patients. To this end, we have recently carried out some design studies on special headbands that should be useful in mitigating severe head injury when bipedally unstable geriatric patients lose their balance and fall. In this work, UMass Dartmouth has arrived at a headband design that employs their invented Flocked Energy Absorbing Material (FEAM) concept. FEAM is a new entry into the impact energy-absorbing materials field. Here, upright-oriented textile fibers are enclosed in a planar fabric sandwich layer structure. Here, the layer material’s impact force cushioning/absorption mechanism involves the frontal bending/buckling of the upright fibers and the inter-fiber friction that occurs when the upright fibers are deformed during impact. This impact force cushioning effect is very similar to the cushioning effect one gets when walking across a high-pile fiber rug. Conclusively, this FEAM structure is found to have great Impact Force Absorption (IFA), is breathable, sweat absorbing, and is robust enough to be fabricated into many types and shapes of wearer-comfortable sport, military, and domestic IFA pad applications [2-5]. Applying this FEAM technology to the field of geriatric headbands has led to the creation of the workable prototype headband design that is the subject of this publication. Summarizing, UMass–Dartmouth’s geriatric headband design consists of an open, one-size-fits-all, wrap-around “band” structure. This novel, comfortable, body-heat and sweat-managing, one-size-fits-all headband structure is referred to by the acronym WAPH for Wrap Around Padded Headband.

Experimental details

Materials

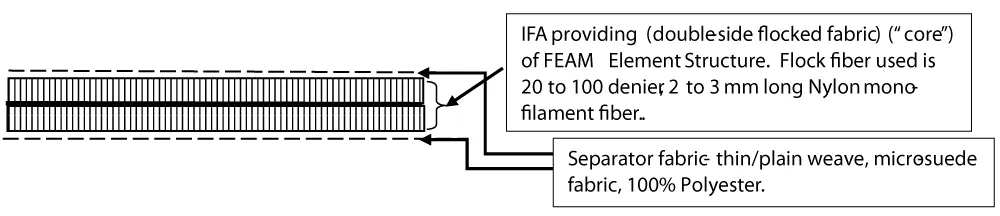

Material components: The impact-absorbing materials used in these prototype headbands employ Flocked Energy Absorbing Materials (FEAM) as their core element. Flocking is a special textile process where short fibers are electrostatically aligned and propelled into an adhesive-coated surface (planar fabric). The electrostatically propelled fibers orient themselves into the uncured adhesive coating in an upright position; the system is then cured locking the upright fibers in place. If low denier (1 to 5) (small diameter) fibers are used, the process results in forming a fabric layer having a smooth, velvety surface. When higher denier fibers are used (20 to 130 denier), as needed for FEAM configurations, the flocked surfaces become springy and impact-absorbing. However, here, the flocked surface must be covered with a thin, plain weave fabric separator or divider fabric. This separator fabric serves to spread out the number of flock fibers that can participate in the compressional deformation process. In our work, all the flocked materials used were obtained from Corsair Innovations, Plymouth, MA. Furthermore, in this now-reported work, all the WAPH structures were fabricated using three material components:

- Double-side flocked fabric: 20 to 100 denier, 2 to 4 mm long Nylon flock fiber. [Demonstration samples were fabricated using some available at UMD, double-side flocked nonwoven base fabric, flocked with 20 denier, 2 mm long nylon fibers].

- Micro-Suede 100% PET (separator) fabric: JoAnn Fabric, Sew Classic Microsuede. Item # 10486819.

- Velcro® hook adaptable and stretchable outer-wrap fabric. [Gehring-Tricot, Garden City, NY # WW1373 (Nylon-Spandex) Available in colors Almond and Black].

Testing methodology

IFA property measurement: There are many characterization techniques and performance simulation methods for impact energy-absorbing materials [6-11]. A Guided Weight Drop (GWD) test was employed in this study. Here a 5.0 Kg projectile steel weight projectile is gravity-dropped from a continuously adjustable set height of from 25 to 200 cm. The dropped projectile is fitted with an accelerometer to measure strike velocity. The test sample is mounted on a force table which registers the force-time tracing of the impact-action. The “strike face” of the 5 Kg projectile has a 12.5 cm. diameter hemispherical shape. Since the gravity-dropped projectile was fitted with an accelerometer, the kinetic energy of this strike projectile was able to be calculated as 49.0 Joules at a 100 cm drop height. This kinetic energy is calculated from the measured velocity. In the GWD test, Force Loss (FL%) and the impact-projectile’s deceleration value “g” (g-force) are measured and reported as a measure of the specimen’s overall IFA properties. FL% is determined by comparing the measured peak strike force with and without the presence of a test sample mounted on the apparatus’s force table. “g” is calculated by dividing the strike velocity by the Impact Duration Time (IDT).

Water absorption measurement: A water immersion test of the fabricated FEAM panels was devised as a means of simulating the ability of the created WAPH structures to absorb sweat. This test involved simply immersing a set physical size of the FEAM material in room temperature water and measuring the water pick-up at various immersion times. The water pick-up measurements we carried out by (1) removing the FEAM test sample from the water. (2) allowing it to “drain” for three seconds, (3) weighing the sample and (4) re-immersing the sample in the water. This procedure was carried out in as smooth and routine timing as possible. Resultingly, most of the measurement errors in the test occurred in the first 5-minute time period of the test.

Results

WAPH design studies

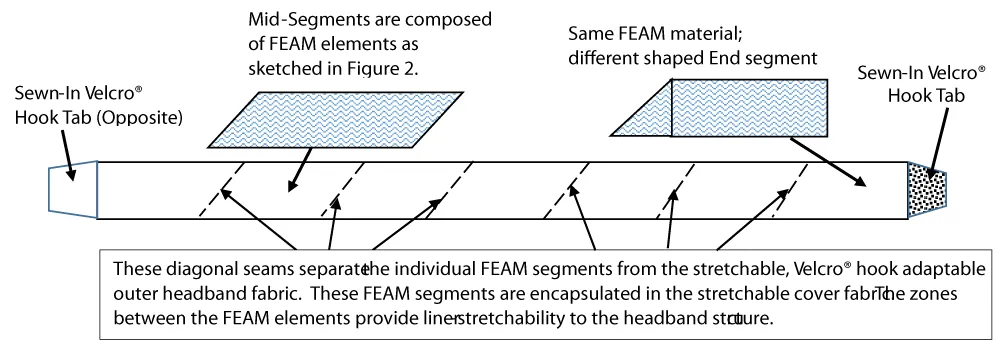

Initial design considerations were first delineated in that it was determined that the final headband design had to be (1) linearly stretchable, (2) soft and wearer comfortable, (3) one-size-fits-all features, and (4) have excellent IFA properties. With these set specifications, several designs were tried, with the most difficult specification being able to satisfy the linear stretchability property. To this end, we were fortunate to have found a commercially available fabric product from Gehring-Tricot, Long Island City, NY that had the unique combination of stretchability (Spandex® containing) and Velcro® hook adaptability. The fabric has the G-T designation of WW-1373. This fabric was found to be eminently useful for our design experiments. From this, after a series of fabrication of several design variations, a final headband design was established. This final design is sketched in Figure 1. Component details of the important FEAM segments depicted in Figure 1 are presented in Figure 2.

From the diagram in Figure 1, we see that each IFA segmented component of the headband “strap” is composed of a diagonal-shaped FEAM element as diagramed in Figure 2. Note from Figure 1 that a headband design composed of seven segments is shown (five mid-segments and two end segments). During the experiments, 28-inch long headband designs made using five, six, and seven “segments” were fabricated. It was found that the seven-segment headband design was the most easily stretchable and most wearer comfortable. Therefore, the seven-segment WAPH was selected for our premier headband configuration.

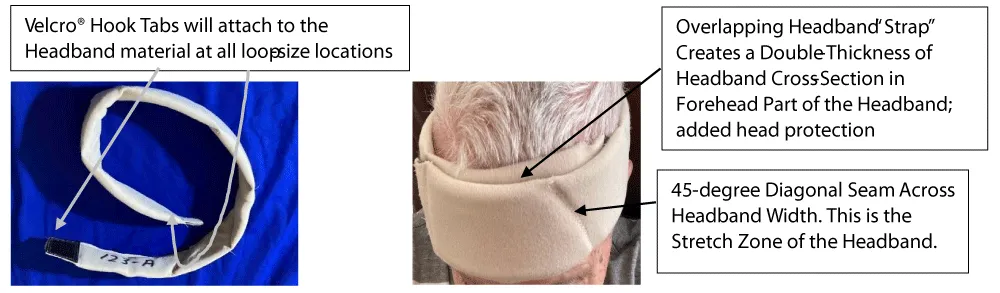

When fabricating the final headband, the seven, diagonal-shaped FEAM elements are linearly positioned along a length of stretchable Velcro® hook adaptable fabric (WW 1373). The headband structure is then finalized by folding over the WW 1373 fabric and stretch-stitch sewing along the folded-over length of the cover fabric. Next, the individual, diagonal-shaped FEAM elements are sewn into position to create independent, pockets of the FEAM segments along the length of the headband. Care is taken not to accidentally sew the outer WW 1373 stretch fabric onto the enclosed FEAM segments during this diagonal-width sewing step. The final step involves sewing Velcro® hook strips/tabs onto the opposite ends of the assembled band. Photographs of the finished geriatric WAPH are presented in Figure 3. To culminate this part of UMass Dartmouth’s geriatric WAPH development, the salient features of the developed headband are summarized in Table 1. This Table presents evidence of the effectiveness of the prototype design.

Experimental evaluation of developed WAPH configurations

IFA properties: Prototype headband test (material cross-section) configurations were fabricated and impact tested; results are presented in Table 2. All the tested samples were prepared using Gehring-Tricot’s WW1373 stretchable Velcro® loop fabric. Referring to Table 2, test panel 036-A is the “control”. Note here that all the flock fiber layers containing WW1373 stretch-fabric configurations have better IFA properties than the CONTROL (no flock treatment). FEAM-based IFA treatments provide the needed IFA properties to the final WAPH design. More GWD testing studies should be carried out to determine the optimum IFA-performing FEAM element for WAPH applications. Wearer comfort testing was carried out configuration was found to be comfortable for a longer wearing time (over 5 hours).

By self-fitting the headband and subjectively evaluating the results. The designed geriatric WAPH.

Research is continuing leading to optimizing the IFA performance of the FEAM element. One may ask here why IFA foam materials were not studied in this headband design study. While foam materials are excellent IFA materials (vinyl nitrile foam is a good example) they fully lack longitudinal stretchability. In addition, they are not very conformable to convex shapes. Also, closed-cell foams are not at all good for sweat and body heat managing materials. Because of this, IFA foam materials were not considered in our study.

Water pick-up properties: As mentioned previously, prototype geriatric WAPH designs have been successfully trial-worn by the authors as a means of judging wearer comfort. In this context, it was decided to determine the water absorption behavior of FEAM and other headband fabric materials to gain knowledge as to how these WAPH structures would handle the absorption of sweat. Table 3 presents the results of our very brief study. As shown, the FEAM containing headband materials performed very well in the water pick-up test. The FEAM configuration compared very well to the water absorption behavior of the layered terrycloth fabric; keep in mind that terrycloth is the fabric from which drying (bath) towels are fabricated. The data in Table 3 gives good confidence that FEAM employing geriatric headbands should serve very well in managing sweat and body heat.

Concluding remarks

This publication summarizes progress to date on applying UMass Dartmouth’s FEAM technology to the field of geriatric (fall, head protection) headband applications. Demonstration (prototype) Wrap-Around Padded Headband (WAPH) structures have been fabricated and successfully studied for comfort, IFA properties, and moisture absorption. With this, let it be known that all of the UMD laboratory fabricated demonstration headband samples were prepared using double-side flocked, 20 denier, 2 mm long nylon flock fabric material that was available at the UMD laboratory. It is known that this is NOT the optimum Impact Force Absorption (IFA) flocked fabric padding configuration for this application. It is known that higher denier (60 to 130 denier) and longer (3 mm to 4 mm) Nylon flocked fiber, double-side flocked fabrics should be used and herewith evaluated. FEAM configurations employing higher denier, longer flock fibers will result in creating much higher IFA-performing body protection pads including headbands [2,3].

Overall, it is realized that the herein-described headband design, while most conveniently custom-adjustable to the wearer’s comfort, will always result in a thicker desirable headband strap. However, this feature may not be of particular importance in geriatric applications; aesthetics would be of secondary importance. The greater thickness of the designed WAPH would be an advantage. As shown in the design, there is a built-in overlap section of the wrapped band; this feature should be taken as an advantage. The overlap creates a section of the headband that is of double thickness. Furthermore, the geriatric wearer has a choice of placing the overlap section of the headband on the forehead or at the back of the head; it is recognized that many geriatric falls occur in the backward direction. The wearer has a choice. Actually, by design, this overlap length can be increased or decreased depending on the chosen length of the original band configuration. While this headband overlap issue results in a thicker headband section, it may become a fashion issue for some of the WAPH wearers. If aesthetics becomes an issue, WAPH of different colors or some with decorative logos could be devised. Overall, though, these adjustable-sized headbands should be much more versatile than the fixed-size headband types. Extending the presented headband ideas, it is conceivable that such a wrap-around IFA pad-like garment could be designed for geriatric around-the-hip garments. Such would help to mitigate hip fractures in a senior’s fall occurrence. On another issue, these adjustable headbands could also be used as emergency medical tourniquets. More market studies need to be carried out on the concept of UMass Dartmouth’s WAPH adjustable IFA headband concept. Overall then, the work presented in this publication should serve as a solid precursor to commercially developing WAPH and like-products for geriatric applications.

The authors wish to thank the University of Massachusets, Office of Technology and Commercial Ventures (OTCV) for the partial sponsorship of this padded headband research.

- Anon. More Older Americans are Dying From Falls. AARP Bulletin. 2023; 64: #9.

- Armand LF, Matos H, Rice JM, Kim YK. Impact force loss behavior of flocked surfaces. Textile Research Journal online. November 25, 2016. DOI: https://doi.org/10.1177/0040517516679149

- Kim YK, Chalivendra VB, Lewis AF, Fasel B. Designing flocked energy-absorbing material layers into sport and military helmet pads. Textile Research Journal. 2021. DOI: 10.1177/ 00405175211010689

- Matos H, Kim YK, Lewis AF. Experimental and finite element analysis of a novel flocked energy absorbing padding material. In: Proceedings of papers presented at the Fiber Society Meeting, Drexel University, Philadelphia, PA. 22–24 October 2014; 256–259.

- Matos H. Energy absorption of flocked materials during impact. MS Thesis, UMass Dartmouth Department of Mechanical Engineering. 2014.

- Mills N, Wilkes S, Derler S. FEA of oblique impact tests on a motorcycle helmet. Int J Impact Eng. 2009; 36: 913–925.

- Kleiven S. Influence of impact direction on the human head in prediction of subdural hematoma. J Neurotrauma. 2003 Apr;20(4):365-79. doi: 10.1089/089771503765172327. PMID: 12866816.

- Hisley D, Gurganus J, Drysdale A. Experimental Methodology using digital image correlation to assess ballistic helmet blunt trauma. J Appl Mech. 2011; 78: 1–7.

- Liu Y, Hu H, Zhao L. Compression behavior of warp-knitted spacer fabrics for cushioning applications. Textile Res J. 2012; 82(1): 11–20.

- Shim V, Lim C, Foo K. Dynamic mechanical properties of fabric armor. Int J Impact Eng. 2001; 25: 1–15.

- Li Z, Sun B, Gu B. FEM simulation of 3D angle interlock woven composite under ballistic impact from unit cell approach. Comput Mater Sci. 2010; 49(1): 171–183.

Article Alerts

Subscribe to our articles alerts and stay tuned.

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Save to Mendeley

Save to Mendeley